Founder and Director of LMAC Consulting, Nigel Reaney is passionate about developing stronger, more profitable business organisations. Here he discusses what Industry 4.0 means for New Zealand’s SMEs.

As a manufacturing expert over the last three decades, I’ve seen a lot of productivity fixes and fads come and go. In recent years, one trend to rule them all has emerged: “Why are we still manufacturing onshore?”

I’ve heard this rhetorical question asked countless times in New Zealand boardrooms. The tone of the question almost always implied the answer was obvious: “Of course we should move our manufacturing offshore. That’s the solution to all our problems.”

CEO’s with experience of managing offshore manufacturing facilities were in high demand. They’d ride into an organisation on their high horse and usually move onto their next gig before the carnage of their overseas adventure became clear. Poor quality products, high minimum orders and long lead times are just a few of the problems associated with moving manufacturing offshore.

Ironically, a new generation of consumers, not CEOs, has forced companies to rethink the accepted wisdom of trusting their manufacturing process to offshore agents. Consumers today want customised, specialised products and instant gratification and delivery. Sluggish supply chains just won’t cut it. This changing consumer environment presents an opportunity for New Zealand manufacturers.

This country is already adept at low volume, high product mix manufacturing and if our industry leaders have the courage and foresight to make some big decisions, we can repatriate many of the manufacturing processes that have been lost overseas in recent years.

In order to exploit this opportunity, we need to take advantage of rapidly advancing and affordable technologies. We need to be leaders, not laggards. These technology advancements are not insignificant; what we’re talking about is nothing less than the next industrial revolution, the ‘Fourth Industrial Revolution’ to be exact.

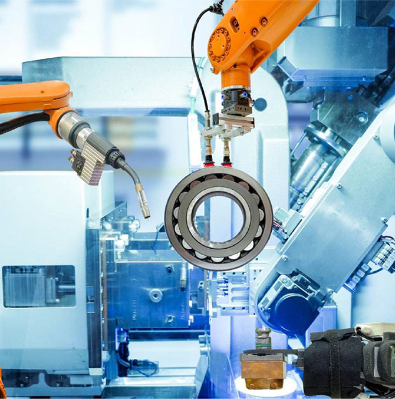

The term Industry 4.0 was developed in 2011 by a working group commissioned by the German government. The concept includes advancements in automation, new technologies and perhaps most importantly, data-driven artificial intelligence (AI). Ultimately, the vision is for ‘smart factories’ that will operate autonomously and without the need for humans. Low labour costs are the main competitive advantage enjoyed by the Asian manufacturing powerhouses. ‘smart factories’ will level the playing field.

For pessimists and technophobes, the very notion of ‘smart factories’ may conjure up dystopian images of The Terminator or The Matrix. Optimists and technophiles realise that change is inevitable and if New Zealand can embrace Industry 4.0, the country will benefit from a revitalised manufacturing industry.

Revolutions are scary and previous industrial revolutions have made many low-skilled jobs, and the humans who perform those jobs, redundant. However, humans are a resourceful species and ultimately the three previous industrial revolutions have led to dramatic growth, improved standards of living and the need for more highly skilled jobs. There’s no reason to expect any other outcome from the next revolution. Whether we like it or not, growth from mass manufacturing, low wage economies has run its course and Industry 4.0 will change the playing field.

As with any major change, there will be winners and losers. Some New Zealand companies are already benefiting from Industry 4.0 technologies, which is encouraging to see. New Zealand industry leaders need to show faith and courage in technology if individual businesses and the manufacturing sector across New Zealand want to be on the winning team.