We’ve read the headlines of established manufacturers and even Formula 1 teams rapidly adapting their manufacturing processes to produce essential products. This type of response really shines a light on the fact that demand truly does breed innovation. But this type of innovation is not just for producing an entirely new product.

Once the gates of manufacturing re-open, many will face significant changes in both supply of materials and demand for products. In these situations, a major problem is process bottlenecking and subsequent problems with output and productivity. As a team of experienced process engineers, we’ve encountered many of these issues in the past, and used tools most associated with the Theory of Constraints to address them.

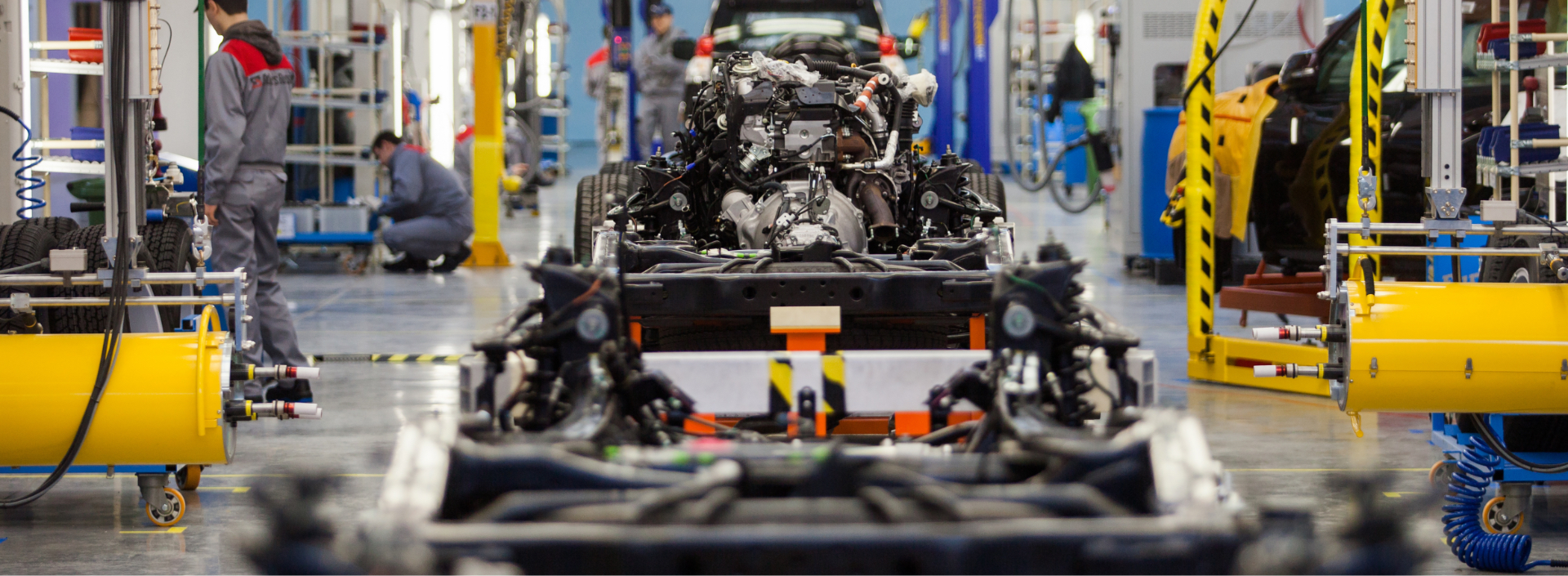

So, through a series of blogs we’re going to share some of those experiences across different manufacturing and processing environments and share some handy tips. We’ll keep jargon to a minimum and focus on what we think may help NZ manufacturing get off to the best possible manufacturing restart. We’ll start off with an assembly line scenario.

Assembly line De-Bottle-necking tips for temporary production demand

- Table-Top manufacturing

Things don’t need to look pretty to make a quality product efficiently and safely. Look at setting up a second assembly line using “table-top” principles.

- Find unused table surfaces from offices, storage, or even buy some cheap ones from an office supply company.

- Establish what assembly fixtures can be replicated quickly and cheaply in-house or by a local engineering company. Remember, for temporary demand these do not need to be of the same durability of line 1 equipment. Think soft tooling and perhaps even 3D printed jigs and fixtures.

- Establish what equipment can’t be replicated quickly and cheaply. Measure the operating cycle time for this equipment.

- For equipment with cycle times short enough to feed 2 lines, de-flow this process from the original line 1.

- If there are several pieces of equipment that need to be de-flowed, make a temporary production cell to make “full work” content for 1 or multiple operators.

- For equipment that cannot feed 2 production lines (constraint equipment), de-flow it from line 1 and put this equipment onto multiple shifts. Do a one-off WIP inventory build that acts as “elastic” (inventory builds on the extra shift and depletes on the primary shift).

- Mitigate risks of inventory build (quality) with additional quality checks.

- Covid distancing between processes. Where 2m distance cannot be achieved, look at temporary screens. Where 2m distance can be achieved, look at making cheap and temporary chutes that use gravity to transport WIP between processes using 1-piece flow technique.

Look out for our next blog that will cover a food processing scenario.